Home > Technology Top > Product Technology > Mini Bottle Can

These plastic cups/containers can be made multi-layered by deep-draw-vacuum-thermoforming.Direct print by offset on exterior surface can produce by small lot and shorter lead-time.

-

1.Threading the neck

Advanced threading technique is applied on the small 100 ml cans, with a 28 ml diameter, the same as with ordinary beverage cans.

-

2.Metal caps

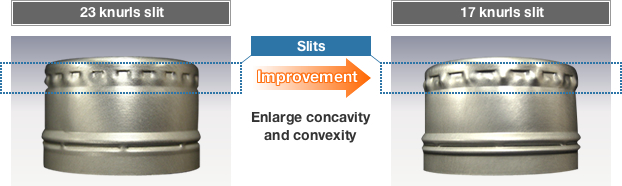

Concavo-convex on the caps is improved, which reduces slipperiness on the fingertips when opening the cans.

- 17 knurls slit

-

By reducing the number of knurls from 23 to 17, the upper part of the metal caps have larger concavity and convexity, which reduces slipperiness on the fingertips when opening the cans, and enforces the overall grip.

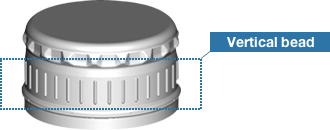

- 34 vertical bead line cap

-

To further reduce slipperiness on the fingertips when opening the can, 34 bead lines for enforced grip.

-

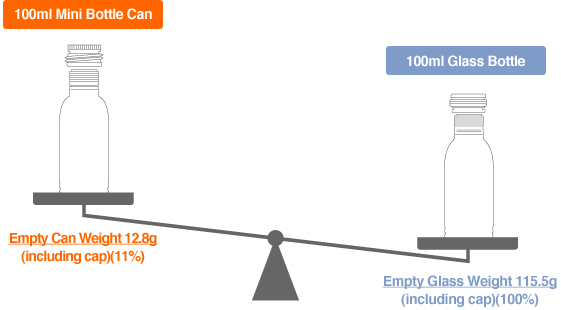

3.Lightweight

Compared with containers of the same size, the Mini Bottle Can is very light. At only 12.8 grams, it weighs 89% less than glass bottles, shatter proof as it is metal. The bulk is only 88% of that of glass bottles, so distribution costs should decrease.

-

4.Printing to shoulder

To satisfy diversified customer needs, we have made possible a comprehensive package design (the cap and body), enabling overall printing with free design for the whole container.